|

View the ADU series of USB based Data Acquisition Products

View the ADU series of USB based Data Acquisition Products

Introduction

Communicating with USB devices in LabView, or

virtually any application software, involves a few

simple steps. Unlike RS232 based devices which are

connected to physical COM ports, USB devices are

assigned a logical handle

by operating systems when they are first plugged in.

This process is known as enumeration.

Once a USB device has been

enumerated, it is ready for use by the host computer

software. For the host application software to

communicate with the USB device, it must first obtain

the handle assigned to the USB device during the

enumeration process. The handle can be obtained using an

open function along with

some specific information about the USB device.

Information that can be used to obtain a handle to a USB

device include, serial number,

product ID, or vendor

ID. Once the handle is obtained, it is used to allow the

application to read and write information, to and from,

the USB device. Once the application has finished

with all communication with the USB device, the handle

is closed. The handle is generally closed when the

application terminates.

The AduHid DLL provides all the

functions to open a handle, read and write data, and

close the handle of ADU USB devices. The ADUHID dll can

be used directly from a LabView application. The

following example VI demonstrates how to OPEN a handle,

SEND commands, RECEIVE data, and finally, CLOSE the

handle to the ADU USB device when the program is stopped

or closed.

The sample program below is a

rendition of our AduHidTest program demonstrating the

proper method to utilize the functions within the

ADUHID dll to communicate with ADU, USB based data

acquisition products. If you have never used ADU, USB

based devices, it is recommended that you first download

and run the AduHidTest software to become familiar with

the process of communication with USB devices in

application software. A tutorial and download link is

located HERE.

This basic example VI demonstrates manual communication

with an ADU, USB device. Note that the VI is for a

single connected ADU device only as it opens the first

enumerated ADU device it encounters.

Lets have a look at the front panel.....

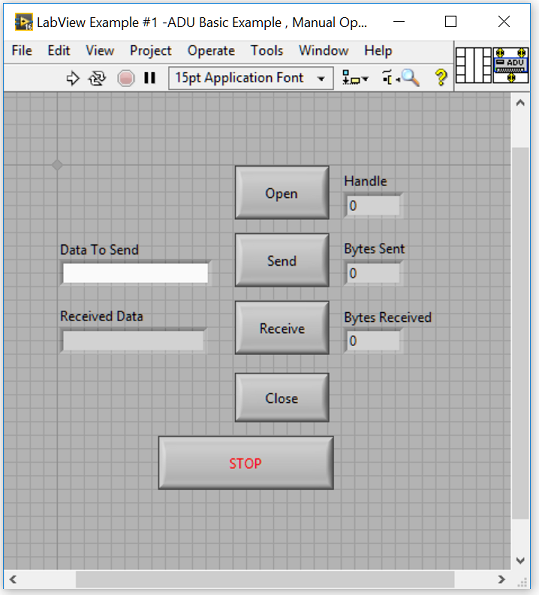

Figure 1. LabView Example # 1 ADU Basic Example - Manual

Operation - Front Panel

The front panel controls are very similar to the

AduHidTest application and include a button to

Open a handle to the connected ADU device, a

button to Send data contained in the

Data To Send string control, a button

to Receive data from the ADU and

display it in the Received Data string

indicator, and finally, a button to Close

the Handle to the ADU device. Numeric indicators

displaying Handle, Bytes Sent and Bytes Received are

also visible to aid in understanding the operation of the

VI. A STOP

button is used to stop the VI, and close the open

handle, if any.

Lets have a look at the block diagram for the VI.

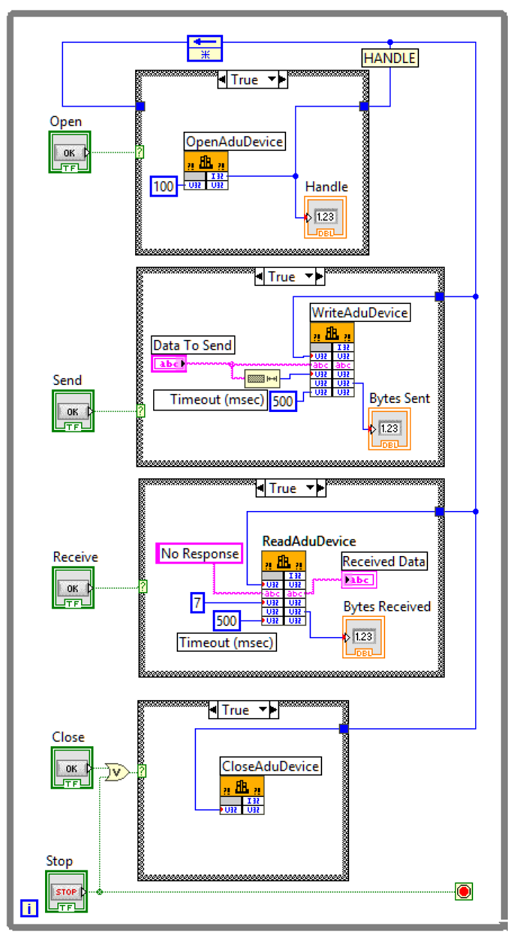

Figure 2: LabView Example # 1 ADU Basic Example - Manual

Operation - Block Diagram

The block diagram is made up of four case

structures to facilitate manual communications

with ADU, USB devices. Each case structure

contains a specific call library function

to access related functions contained in the

AduHid.dll. Note that for proper operation of the

VI, the dll should be located in the same directory as

the VI.

The OPEN function.

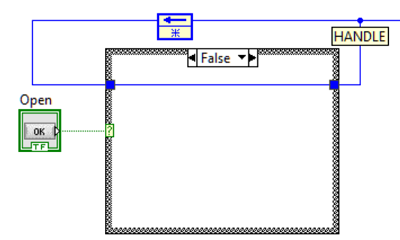

The first case structure is used to obtain a handle to

the connected ADU device and place it on the wire

labeled HANDLE. Note that a feedback node is used

in the case structure to hold the handle value on the

wire when the Open button is released. It is wired

straight through in the False state as seen in Figure 3.

Figure 3: Feedback Node wiring in

Open Case Structure in False state.

When the Open button is pressed, the Windows assigned

handle will be present on the wire labeled HANDLE. This

handle is then used by the Send and Receive functions to

communicate with the connected ADU device. In this

example VI, the handle is selected for the first

available ADU device found in the Windows registry with

the Vendor ID for Ontrak Control Systems.

Additional functions are available to open an ADU device

by Serial Number or Product ID

for use in multiple ADU applications. See the ADU

Windows SDK for details

HERE.

IMPORTANT NOTES - Using

Windows USB Handles

1. Only open one handle to any particular USB device

and ensure it is closed when the program terminates.

Opening multiple handles, without first closing unused

handles, will cause a handle leak in the

Windows operating system. If too many handles are

opened, Windows will disable further USB communications.

2 The handle should be opened when the program

starts, or communication with the ADU device commences.

3. The handle should be closed only when the program

is stopped, or terminates.

4. DO NOT open and close the handle every time

communications with the USB device is required. The

handle should remain open until the program is stopped

or terminates. This is particularly important in newer

versions of Windows with USB Selective Suspend

enabled as, if no handle is open to the USB device,

Windows will suspend the device causing a loss of power

for the output stage on some ADU devices. ADU devices

that will lose output states on loss of power ( suspend

) include, the entire ADU70 series, ADU228, ADU258,

ADU222, and the ADU252. ADU devices that maintain

output states in suspend mode include the ADU100,

ADU200, ADU208 and ADU218.

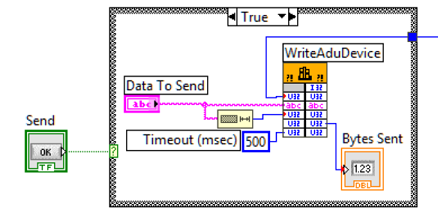

The SEND Function.

Figure 4: The Send function.

When the Send button is activated, text typed into

the Data To Send string control is sent

to the ADU device provided a valid handle has been

obtained. The text string should be a valid ADU command

for the connected device. Consult your ADU User Manual

for a list of commands available. The WriteAduDevice function requires the text

string, along with the number of bytes in the text

string it is sending. The number of bytes in the text

string is obtained using a string length

control and connected to the appropriate node of the

function. The only additional requirement is a timout

value which was set to 500ms using a numeric

constant.

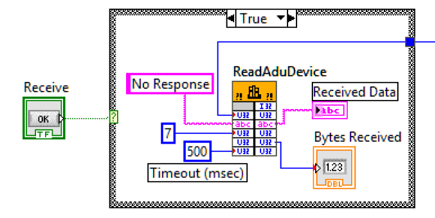

The RECEIVE function.

Figure 5: The Receive function.

If the command sent to the ADU device is a responsive

command, or one which returns data, that data can be

retrieved using the ReadAduDevice function. When the

Receive button is activated, any data the ADU returned

is transferred to the Received Data

string indicator. The "No Response" fixed string

is a placeholder that is passed to the Received

Data string indicator if no data was returned

by the ADU device. The numeric constant "7" is a dll

input indicating how many bytes are to be received.

Note that the number of bytes received will either be 7

for low-speed ADU devices, or 63 for full-speed ADU

devices. The only additional requirement is a timout

value which was set to 500 ms using a numeric

constant.

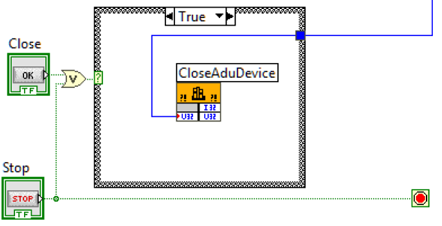

The CLOSE function.

Figure 6: The Close function.

The CloseAduDevice function should be called when the

program is terminated, or, if desired, the user manually

closes the handle to the USB device by activating the

Close button. Note that the program STOP button is OR'ed

with the Close button so that either

can close the handle to the ADU device.

Final Notes....

This VI provides basic functionality only. Many

additional functions are available through the AduHid

DLL including , error codes, device lists, etc.

Future LabView examples will demonstrate these

additional functions including ADU device specific

examples.

DOWNLOAD LabView Example

#1 VI including AduHid DLL ( 2016 and 2009

versions)

|